The supplementation of copper has become commonplace among poultry producers thanks to its well- known beneficial effects on bird performance. Copper acts as a critical cofactor in multiple enzyme systems integral to energy metabolism, tissue growth, red blood cell formation, oxidative defence and immunocompetence.

Copper has also been demonstrated to positively affect the composition of gastrointestinal microflora. As producers reduce their dependence on antibiotics, alternative feed additives like copper show great promise to maximise production efficiency while maintaining bird health.

Although the benefits of copper as a feed additive are widely acknowledged, not all sources of copper are equally effective due to inherent differences in molecular structure. For example, copper sulphate has weak ionic bonds resulting in high water solubility.

This means the bonds break easily in the presence of moisture, releasing positively charged copper ions. Reactive copper ions can reduce feed palatability, damage vulnerable tissue in the digestive tract, and bind with other nutrients in the feed, reducing their availability to the bird.

Despite these negative attributes, copper sulphate has been consistently employed as a feed additive in poultry production since the 1930s. Scientists have since seized on the opportunity to develop new sources of dietary copper without the negative characteristics of copper sulphate.

During the 1980s, chelated copper sources with lower reactivity were introduced to the market; however, their manufacture requires relatively expensive protein feedstocks, resulting in a higher cost product.

In the 1990s, technological advances in applied chemistry allowed for the development of hydroxy copper. Hydroxy copper has many of the same beneficial characteristics as chelated copper (low reactivity and high bioavailability) but at a considerably lower production cost.

Nonetheless, the small price difference between hydroxy copper and copper sulphate still precludes the complete replacement of copper sulphate in some production environments.

Poultry producers, integrators and nutritionists must acknowledge cost differences while still carefully considering the many advantages of using advanced copper sources to replace copper sulphate for the four following reasons:

1. Reduced feed intake

Where permitted, copper is commonly added to poultry diets at concentrations above the nutritional requirement to maximise performance. Prior to the development of less reactive sources of copper (hydroxy copper), supplementation with more reactive sulphate sources was generally limited to levels at or below 125ppm. This is because research indicates feed intake decreases with increasing concentrations of dietary copper sulphate.

Conversely, sources of copper with lower water-solubility allow for higher supplementation levels without corresponding drops in feed intake. Therefore, feeding less reactive copper sources gives producers the flexibility to increase dietary concentrations to optimise the performance of their flocks.

The underlying basis for the difference in feed intake comes from copper sulphate’s high-water solubility. Free copper ions are generated any time feed encounters moisture, during either the feed manufacturing process or feed consumption.

These charged copper ions can damage the mucous membrane of the gastrointestinal tract. Birds will voluntarily reduce their feed intake if they have copper-induced lesions in their mouth, proventriculus or gizzard.

Moreover, ions generated by copper sulphate and water produce free radicals that oxidise dietary fat and vitamins, reducing feed palatability, and further reducing feed intake.

2. Reduced vitamins in feed

Regulations on copper supplementation to poultry feed vary widely across different regions of the world. Research has demonstrated that even nutritional levels of copper sulphate (10ppm) can have detrimental effects on valuable dietary components.

Prices for fat-soluble vitamins A and E have increased dramatically and are expected to remain high throughout much of 2018. Again, low levels of copper sulphate have been shown to have negative effects, accelerating vitamin degradation when compared to less reactive sources like hydroxy copper.

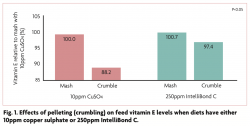

The risk of oxidation increases when the combination of copper sulphate and fat-soluble vitamins encounters moisture and heat during the feed manufacturing process. Free copper ions participate in oxidation reactions, generating free radicals. These free radicals interact with fats and fat-soluble vitamins, denaturing them in a rapid chain reaction. To test the effect of copper source of vitamin E levels in feed, researchers compared pelleted diets supplemented with copper sulphate and hydroxy copper. The results indicated that the combination of 10ppm copper sulphate, water and heat during the pelleting process resulted in the destruction of more vitamin E than pelleting diets supplemented with 250ppm hydroxy copper (Fig. 1).

3. Reduced vitamin E in birds

These researchers also reported reduced levels of vitamin E measured in the bird itself, as a consequence of copper sulphate’s oxidative destruction.

When the pelleted diets (10ppm copper sulphate vs. 250ppm hydroxy copper) were fed to broilers over a 21-day period, those receiving 250ppm of hydroxy copper had 21% more serum vitamin E and 55% more liver vitamin E compared with birds fed the copper sulphate diet.

In addition to the oxidative damage copper sulphate does to expensive vitamins, producers should also consider the health and performance consequences of reduced vitamin E levels in the bird. Vitamin E is a powerful antioxidant that supports safeguarding the structural integrity of cell membranes, reproductive health, immunity, and normal neurological functions in poultry.

4. Reduced mineral and nutrient digestibility

It is important to remember that the charged copper ions released from the combination of copper sulphate and water do harm to dietary constituents beyond the oxidation of fats and vitamins.

Any negatively charged nutrient (phytate, phosphate, amino acids, fats, sugars) is susceptible to a chelation reaction with positively charged copper. Some of these reactions are irreversible, leading to the loss of both the copper ion and nutrient.

Unlike copper sulphate, which releases its reactive copper ions in the upper gastrointestinal tract, hydroxy copper ions are released slowly and consistently throughout the entire length of the small intestine due to their strong bonds and crystalline structure.

Therefore, feeding hydroxy copper instead of copper sulphate not only improves mineral digestibility, but also does not impede the digestibility of other nutrients.

A strategy for moving forward without copper sulphate

In response to the concerns associated with using copper sulphate as a feed additive, scientists have developed novel forms of copper supplementation, including both chelated and hydroxy trace minerals.

Although chelated copper sources avoid many of the consequences associated with copper sulphate, their costs (up to 10 times the cost of sulphate) are prohibitive for many producers.

For this reason, some producers have compromised by supplementing a small fraction of chelated copper in combination with copper sulphate. As research continues to emphasise the various negative consequences of feeding copper sulphate, complete removal of copper sulphate from the diet becomes more appealing.

With the advent of hydroxy copper, producers now have an option to gain all the benefits of completely replacing copper sulphate with a less reactive copper without compromising the economic viability of their feeding programme.

Written by Kurt Perryman, Technical Sales Manager Micronutrients.

Source: International Poultry Production Vol. 26 No. 3